The Future of Aluminum Foundries: Technologies and trends Forming the Industry

The aluminum foundry sector is going through considerable makeover. Key patterns highlight the significance of sustainability and performance. Technologies in wise production and automation are coming to be widespread. Factories are increasingly focused on utilizing recycled products. This shift raises inquiries concerning future techniques and modern technologies. How will these modifications impact manufacturing methods and market characteristics? The answers might redefine the sector landscape in unanticipated means.

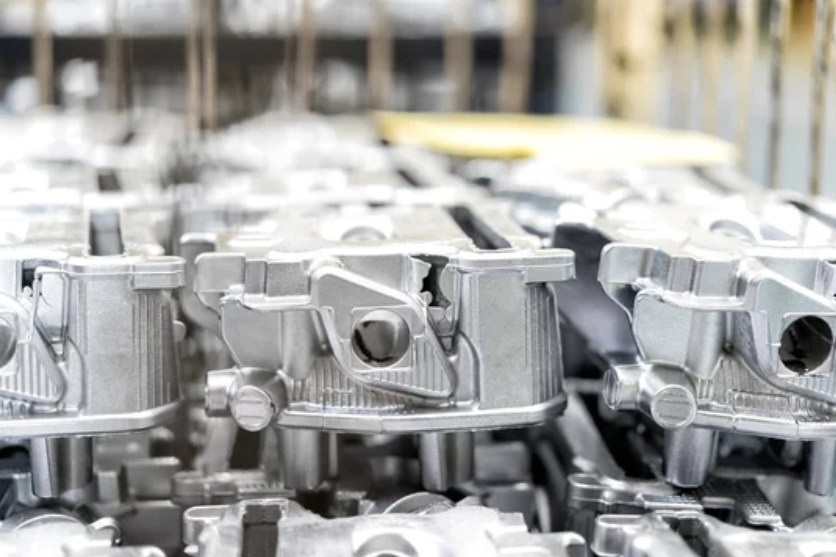

Advancements in Smart Production Technologies

As the light weight aluminum foundry sector evolves, advancements in clever production modern technologies are coming to be increasingly necessary for improving performance and performance. The assimilation of automation, expert system, and the Web of Points (IoT) is changing traditional foundry procedures. These innovations enable real-time surveillance of processes, enabling for instant modifications that optimize output and reduce waste.

Device knowing algorithms assess production information to determine patterns and forecast maintenance needs, reducing downtime. Robotics are increasingly utilized for repeated jobs, releasing experienced employees to concentrate on even more complex obstacles. Additionally, electronic doubles-- virtual versions of physical processes-- facilitate simulations that can boost style and functional techniques.

The fostering of these wise manufacturing technologies is driving affordable benefits in the light weight aluminum shop sector. By improving operations and boosting decision-making capacities, foundries can meet growing market demands while preserving high-grade standards. The future of aluminum factories is undeniably connected to these technical developments.

Embracing Eco-Friendly Materials and Processes

The aluminum factory market is significantly focusing on environment-friendly products and procedures to enhance sustainability. This shift includes the adoption of sustainable product sourcing, energy-efficient production techniques, and effective recycling and waste administration approaches. By integrating these practices, factories intend to decrease their ecological effect while keeping competitiveness in the market.

Sustainable Material Sourcing

How can light weight aluminum shops enhance their sustainability efforts? Lasting material sourcing has become a crucial method in attaining this objective. By prioritizing recycled aluminum, shops can greatly decrease their environmental impact, as recycled materials require much less energy and less resources compared to primary aluminum manufacturing. In addition, sourcing products from accredited suppliers that abide by environment-friendly practices promotes responsible mining and lessens environmental influence. Foundries are likewise checking out different materials, such as biopolymers and green coverings, to enhance conventional light weight aluminum procedures. Collaborating with stakeholders, consisting of distributors and environmental companies, fosters technology in sourcing strategies. Eventually, accepting lasting product sourcing not only aligns with international sustainability objectives but additionally positions light weight aluminum foundries as leaders in ecologically accountable manufacturing.

Energy-Efficient Manufacturing Techniques

Light weight aluminum factories are significantly embracing energy-efficient manufacturing methods to match their sustainable product sourcing efforts. These techniques focus on minimizing energy usage throughout the manufacturing process. Advanced modern technologies, such as induction melting and maximized spreading processes, are being applied to lower the overall carbon footprint. Additionally, automation and wise production systems improve functional efficiency, enabling far better energy administration. Factories are additionally exploring the assimilation of renewable resource sources, such as solar and wind, to power their operations. By focusing on power effectiveness, light weight aluminum foundries not just reduced production prices however also straighten themselves with worldwide sustainability goals, making sure a much more ecologically accountable technique to light weight aluminum production while satisfying the rising need for environment-friendly practices in the market.

Recycling and Waste Monitoring

Accepting environmentally friendly materials and processes, aluminum foundries are prioritizing recycling and waste monitoring methods to boost sustainability in their procedures. By incorporating closed-loop systems, these facilities are minimizing waste and taking full advantage of resource effectiveness. Scrap light weight aluminum, an easily offered product, is being recycled on-site, greatly minimizing the requirement for virgin materials and reducing energy intake. Advancements in sorting and refining technologies even more promote the recycling of aluminum, making sure that even infected products can be repurposed efficiently. Furthermore, shops are adopting sustainable practices such as minimizing contaminated materials and promoting making use of eco-friendly materials for packaging. This dedication to recycling not only lowers environmental effect yet also boosts the financial feasibility of aluminum factories in an open market.

The Duty of Automation and Robotics

Automation and robotics are significantly changing the aluminum shop market, considerably enhancing production effectiveness. By integrating sophisticated technologies, foundries can decrease labor expenses while simultaneously boosting security standards for their workforce. This change not just simplifies operations however likewise positions the industry for sustainable growth in an open market.

Improved Production Efficiency

Reinventing production processes, the integration of sophisticated robotics and automation innovations has actually ended up being a keystone for aluminum foundries looking for enhanced effectiveness. These advancements enhance workflows, minimize cycle times, and boost product top quality by minimizing human error. Automated systems can keep an eye on manufacturing lines in real-time, allowing for instant modifications that enhance outcome. In addition, robotics facilitate the handling of hazardous materials, making certain more secure workplace while enhancing throughput. Anticipating upkeep technologies also contribute to efficiency by preparing for devices failings, consequently lowering downtime. Therefore, light weight aluminum shops can accomplish greater consistency in their items while reacting more quickly to market demands. This embrace of automation is setting a new criterion for efficiency and operational excellence within the market.

Minimizing Labor Expenses

The shift in the direction of advanced robotics and automation in aluminum factories not just improves manufacturing efficiency but likewise plays a considerable role in reducing labor prices. By integrating automated systems, foundries can decrease the dependence on hand-operated labor, which typically entails high wages and training expenditures. Robotics streamline repeated jobs such as putting, molding, and finishing, enabling a higher output with fewer workers. This technological change not only lowers labor-related prices but likewise enhances consistency and high quality in manufacturing. In addition, automation can operate all the time, maximizing functional hours without the connected prices of overtime or shift differentials. As an outcome, aluminum shops can accomplish considerable cost savings while keeping competitive prices in an advancing market landscape.

Improving Security Requirements

While standard light weight try this website aluminum factory operations frequently reveal employees to unsafe settings, the combination of robotics and automation significantly enhances safety criteria within the market. Automated systems can perform high-risk jobs, such as molten metal handling and heavy training, decreasing human direct exposure to harmful problems. Additionally, robotics can run in severe temperature levels and poisonous ambiences, successfully lessening the risk of injury. Advanced keeping track of innovations and expert system assurance real-time safety analyses, permitting instant feedbacks to potential threats. Automation improves operations, decreasing the probability of mishaps triggered by human mistake. Therefore, the fostering of these technologies not only enhances security but additionally fosters a much more reliable and efficient workplace in light weight aluminum foundries.

Enhancing Energy Efficiency in Manufacturing

As light weight aluminum factories seek to keep competitiveness in an evolving market, enhancing energy performance in production has become an essential focus. By embracing sophisticated innovations such as high-efficiency melting see this heaters and automated temperature level controls, shops can significantly minimize energy consumption. Implementing real-time monitoring systems permits accurate tracking of energy usage throughout the manufacturing process, allowing quick changes to optimize effectiveness.

Furthermore, shifting to alternate power sources, including eco-friendly choices, can additionally reduce the carbon impact. The integration of power recovery systems, which redeem waste warm for reuse, is ending up being significantly usual. Training workers in energy management methods assures that every person associated with the manufacturing procedure is conscious of energy usage.

These efforts not only lower functional expenses yet also straighten with international sustainability objectives, positioning light weight aluminum foundries as responsible gamers in the sector while enhancing their overall competition. - Aluminum Foundry

Technologies in Recycling Light Weight Aluminum

Advancements in reusing light weight aluminum have actually acquired momentum alongside efforts to enhance power effectiveness in production. The light weight aluminum sector has actually accepted innovative modern technologies that improve the reusing procedure, minimizing power usage and environmental effect. Techniques such as hydrometallurgy and brand-new sorting technologies enhance the extraction of aluminum from scrap, boosting yield rates and guaranteeing better recycled material.

Moreover, the development of closed-loop recycling systems permits shops to recycle light weight aluminum without significant deterioration in quality, making the procedure more sustainable. Innovations in logistics and collection, including boosted monitoring systems and automated sorting, have actually additionally played a vital function in enhancing the effectiveness of aluminum recuperation. These improvements not just add to a circular economic climate yet likewise assist minimize the carbon impact connected with light weight aluminum manufacturing. As the demand for sustainable methods grows, these technologies position the light weight aluminum shop field as a leader in accountable source management.

Reacting To Market Needs and Consumer Trends

Adaptability has become a keystone for aluminum foundries replying to evolving market demands and customer patterns. As industries increasingly prioritize sustainability, aluminum shops are moving in the direction of green practices, consisting of improved recycling processes and lowered carbon impacts. This change straightens with customer preferences for environmentally accountable items, driving factories to innovate their offerings.

Furthermore, the surge of light-weight products in automotive and aerospace sectors necessitates improvements in aluminum alloys and casting methods. Shops are buying r & d to create high-strength, light-weight components that satisfy rigorous efficiency standards.

Modification has actually gained grip, with customers looking for tailored solutions. Aluminum shops are leveraging advanced manufacturing technologies, such as 3D printing, to suit certain customer demands efficiently. This responsiveness not just pleases consumer needs yet likewise placements light weight aluminum foundries competitively in a vibrant market landscape, ensuring their significance in an ever-changing industrial environment.

Frequently Asked Questions

Exactly How Do Aluminum Foundries Impact Resident Economies?

Light weight aluminum factories substantially impact local economic situations by producing jobs, stimulating need for local providers, and adding to neighborhood visite site development. Their operations usually result in boosted tax obligation profits, which can money essential public solutions and framework improvements.

What Are the Safety And Security Laws for Aluminum Factory Employees?

Security guidelines for aluminum foundry workers consist of compulsory personal protective devices, appropriate ventilation systems, regular training on dangerous products, and adherence to standards established by work-related wellness and safety and security managements to minimize dangers and warranty worker safety and security. - Aluminum Casting Company

How Does Light Weight Aluminum Recycling Affect Global Supply Chains?

Light weight aluminum reusing considerably minimizes need for basic materials, enhances source performance, and stabilizes costs. This change impacts global supply chains by fostering a circular economy, promoting sustainability, and ensuring a more durable industry in changing markets.

What Career Opportunities Exist in the Light Weight Aluminum Shop Sector?

Different job chances exist in the aluminum shop sector, consisting of functions in design, quality assurance, production monitoring, and research and advancement. Competent labor positions such as mold manufacturers and equipment drivers are additionally popular.

Exactly How Do International Trade Policies Influence Aluminum Foundries?

International profession policies considerably impact light weight aluminum shops by impacting import tolls, supply chain dynamics, and market accessibility. These aspects can affect functional expenses, competition, and overall productivity within the global light weight aluminum production landscape.

By focusing on recycled aluminum, shops can considerably decrease their ecological footprint, as recycled materials require much less energy and fewer resources compared to key light weight aluminum production. Aluminum foundries are progressively embracing energy-efficient manufacturing techniques to enhance their sustainable product sourcing initiatives. Automation and robotics are progressively changing the light weight aluminum shop sector, substantially boosting manufacturing efficiency. The change in the direction of progressed robotics and automation in aluminum factories not just boosts production efficiency but likewise plays a considerable duty in minimizing labor expenses. As aluminum foundries seek to preserve competition in a developing market, boosting power efficiency in manufacturing has actually arised as an important focus.